Applications

There is a Ferro-Tic Grade to Suit your Needs

A two-fold complementary effect is achieved whereby the hard, rounded titanium carbide grains protect the matrix which in turn securely grips the self-lubricating titanium carbide micrograins. The result: greatly improved life, even in the most severe wear applications.

Versatile Ferro-Tic can be anything you need it to be: slippery, hard, tough, magnetic or non-magnetic. It can be used at cryogenic or elevated temperatures. Whether it’s performance that exhibits excellent resistance to abrasion, to vibration, or to corrosion and thermal wear, there’s a Ferro-Tic grade for you.

For tooling, Ferro-Tic provides longer life between sharpenings or regrinds. For draw or forming tools, guides or rollers, the rounded titanium carbide grains at the surface provide lubricity and galling resistance unavailable in other tooling materials. Ferro-Tic’s durability and ease of fabrication simplify its incorporation for use in critical wear parts.

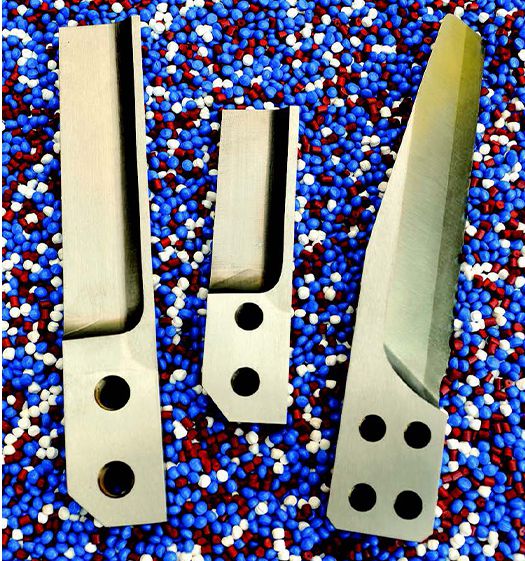

Ferro-Tic is ideal for blades and knives, such as these underwater pelletizer knives, shown with plastic pellets in the background. (Knives provided courtesy of Pelletizer Knives, Inc.)

Screws, Cutting Blades and Industrial Knives

Cutting demands a sharp, keen edge for blanking punches, shear knives, rotating slitters, pelletizer knives or bed knives. The very fine, rounded, slippery titanium carbide grains nestled in a tough metal matrix resist dulling and chipping. Ferro-Tic maintains a sharp cutting edge through millions of cycles.

Industrial Punches, Tools and Dies

Ferro-Tic parts overcome galling and pick-up which are frequent problems when metals rub against each other at high speeds or under heavy pressure. Exposing the Ferro-Tic titanium carbide micrograins at the working surface leaves them in relief and, in effect, minimizes metal-to-metal contact. Their smooth, rounded structure offers an extremely slippery and non-abrasive working surface.

When forming metals such as high-nickel alloys or tough stainless steels, the Ferro-Tic composite produces scratch-free parts through-out long production runs.

Progressive stamping die. Grade C is used to provide wear resistance and ease of machining.

Custom-Manufactured Parts for Aerospace, Hydraulic Components and High Stress Industrial Applications

For critical moving parts, even under conditions of poor lubrication, Ferro-Tic operates with a low coefficient of friction and extended part life.

Ferro-Tic Parts Withstand High Stress Loads

Ferro-Tic alloys offer an impressive compressive strength of up to 520,000 psi to easily withstand high compressive loading without deformation.

With an elastic modulus of 40-44 million psi, about half that of cemented tungsten carbide, Ferro-Tic can take more deflection under stress and transfer more of the applied load to a stronger back-up member.

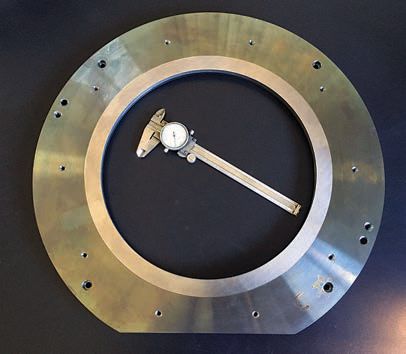

Large diameter paper cutting die.

Waterjet cutting machine. Grade CS-40 is used to provide wear and corrosion resistance as well as rigidity at high pressures.

As technological advances bring about ever higher production speeds and greater stresses, parts subjected to wear that retain their integrity for extended periods of time become more essential.

Ferro-Tic steel-bonded carbides are meeting that demand.

Copper extrusions. Grade HT-6A is used to provide wear resistance at high temperatures.

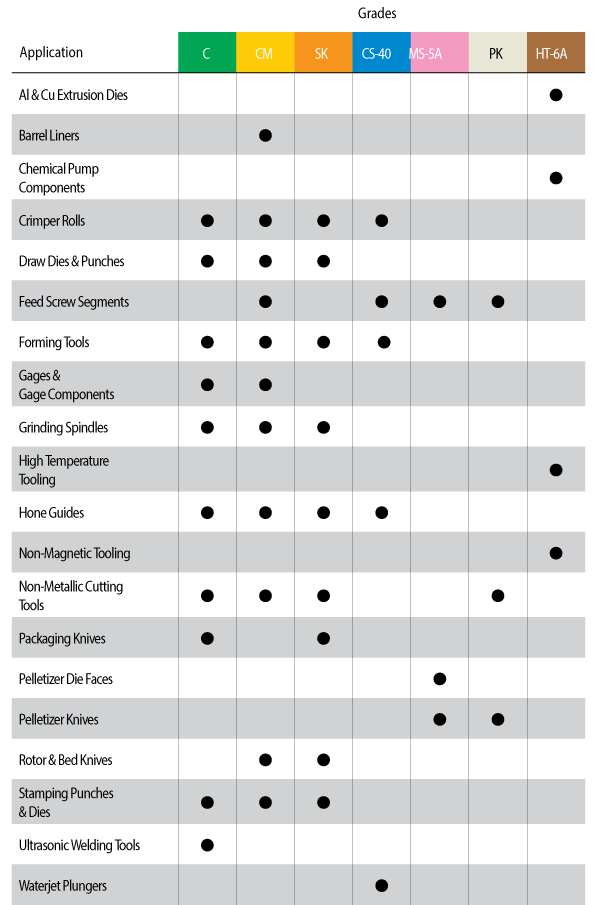

Application Guide

Application Guide

C

CM

SK

CS-40

MS-5A

PK

HT-6A

Al & Cu Extrusion Dies

Barrel Liners

Chemical Pump Components

Crimper Rolls

Draw Dies & Punches

Feed Screw Segments

Forming Tools

Gages & Gage Components

Grinding Spindles

High Temperature Tooling

Hone Guides

Non-Magnetic Tooling

Non-Metallic Cutting Tools

Packaging Knives

Pelletizer Die Faces

Pelletizer Knives

Rotor & Bed Knives

Stamping Punches & Dies

Ultrasonic Welding Tools

Waterjet Plungers